Through a wider market’s vision, thanks to a consolidated know-how and with a view to expanding the offer to its customers,Nuova BN has allocated new resources in the design, development and production of high-tech steam sterilizers, combining the new brand to the traditional production of operating tables and medical devices.

Reliability of the sterilization processes and functionality of the systems are guaranteed by a leading company in highly specialized medical technologies.

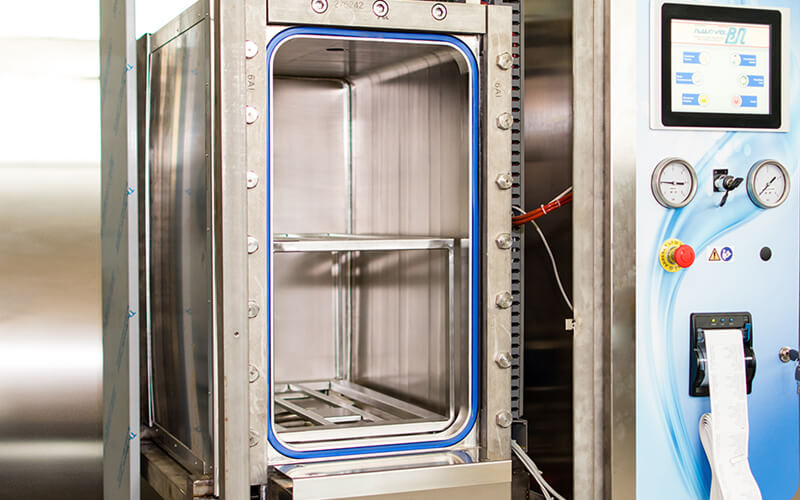

The ST.NBN series is a complete and versatile line of steam sterilizers autoclave for hospital and healthcare facilities, with a variety of models designed for small and large structures.

The devices are developed to meet frequent sterilization cycles designed for operating theatres and sterilization units, respecting the safety of the operator and the working environment.

Certified devices

CE Mark with the number of the Notified Body According to medical device Directive 93/42/EEC

PED certification, according to pressure equipment Directive 2014/68/UE

Conformity to 2014/35/EU Low Voltage Equipment Directive, to 2014/30/EU for electromagnetic compatibility Directive

Compliance with the European reference standard UNI EN 285 for steam sterilizers

Our steam sterilizers autoclave are designed by applying the most advanced technologies in terms of consumption, efficiency and guarantee of results.

The new generation components and construction criteria make it a safe, reliable and a functional product.

Starting from 1 US model to 12 US model, Nuova BN is a company ready to satisfy every requirement of its customers with the aim of making pre and post-operative activities faster and more efficient, following the customer’s needs from the designing of the sterilization hospital units.

NBN ST STANDARD series

The consolidated STANDARD series, after years of presence on the market, is updated with new technologies and functions.

Available in versions from 2 to 12 US, they always guarantee safe and highly efficient sterilization cycles.

Can be made with an additional door on the sterile side, and to complete the configuration, the possibility of positioning the chamber of sterilization to the right or to the left of the technical compartment.

All our sterilizers meet the requirements of Directive 2014/68/EU.

Available configurations

Our steam sterilizers autoclave are available, on request, both in the single door version and in the double door through version.

To complete the configuration, there is the possibility of positioning the sterilization chamber to the right or to the left of the technical compartment, according to the different customer’s needs.

The sterilization chambers

All the sterilization chambers are made of AISI 316 / 316Ti stainless steel, which has essential characteristics to combine sterilization quality and durability.

Furthermore, the construction method, with care for the environment meets the current need for energy saving.

Test cycles according to UNI EN 285

Vacuum Test

Test Bowie & Dick

Helix Test

Sterilizable programs and materials

121 °C |

Rubber and thermolabile materials |

134 °C |

Textile and heat resistant packaged material |

134 °C |

Free instrument |

134 °C |

Packaged instruments and containers |

134 °C |

Prions |

Custom |

Customized or free programs |

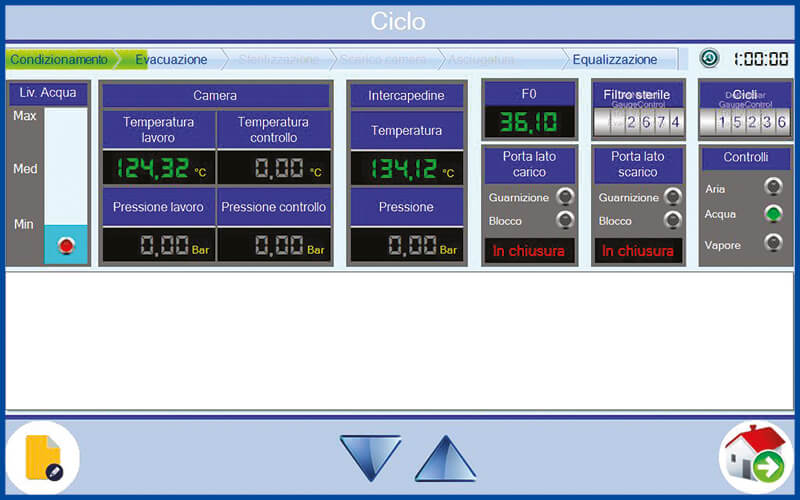

Technology user friendly

Our steam sterilizers autoclave are equipped with a 10 “Capacitive Touch Screen LCD display and with a simple and intuitive user interface it is possible to manage and monitor the various operating cycles of the sterilizer in complete safety.

Thanks to the new generation hardware, Intel Core I3 processor and sophisticated software, the reliability of the system is guaranteed.

As far as models with second door is concerned, it can be expected a control panel with a 5”touch screen display indicating the different functions on the unloading side of the machine.

Traceability

Dynamic and interactive traceability system.

Traceability, in a complex process, is the key to monitoring and managing with speed and attention the surgical instruments during the sterilization phases.

Thanks to a complete I T solution, operators will be supported in managing the workflow during the operational steps remotely and in real time.

System features

The system is mainly composed of a proprietary software,able to perform all the operations,throughout the workflow, automatically, easily and quickly, in order to facilitate the operator in all phases where his presence would be necessary.

By a microchip for the identification of the instruments and/or operators connected to the PC (desktop) stations and connected to the Ethernet network, it will be possible to obtain the parameters of the entire workflow.

From the acquisition of the instruments set to sterilization and to the operator engaged in; from the check up to the data recording, it is all done to be as productive as possible.

For the technical specifications of our steam sterilizers autoclave , refer to the brochure.